Industrial engineering specialized in high-performance solutions for harsh environments, focused on coatings, components, and equipment resistant to wear, abrasion, and impact.

- Revestimentos antidesgaste

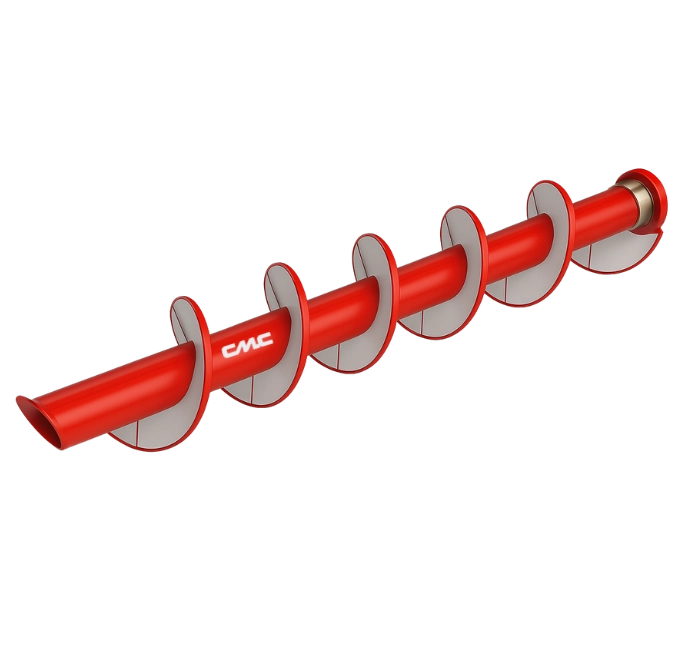

Helicoids

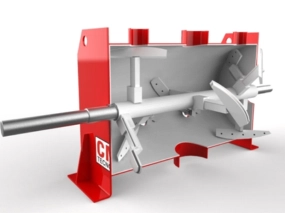

Characteristics: The screw conveyor (helical conveyor) works through the rotational movement of the helicoid and its continuity drives the material along the spiral by friction, it is normally driven by a gear motor. It is also possible to choose other types of activation, in addition to adding sensors, operation indicators, among other components. In our manufacturing process, we prioritize the quality of the seals, as they are responsible for preventing leakage and contamination of the transported material. Screw conveyors are used to transport and control the flow of materials that are in different states, whether dry or with low humidity. Problems with Wear: The friction that occurs during transport between the raw material and the screw conveyor makes the equipment wear out, reducing its useful life, so it is extremely important that the equipment is manufactured with high-strength steel, being carbon steel or stainless steel. However, the direct friction of the material with the best types of steel, depending on the material being transported, still results in accelerated wear, forcing maintenance and sometimes compromising the equipment. Anti-wear Solution: Aiming to solve the problem of wear and corrosion, CMC TECNOLOGIA included in its manufacturing process, the application o Hardtec coating, aiming to obtain greater efficiency and durability, and the results of screw conveyors coated with CMC Hardtec show a significant increase in useful life. The Hardtec coating is composed of high alumina ceramic, material highly resistant to abrasion and corrosion wear and is fixed with special adhesive to ensure maximum efficiency. We have a highly trained team for manufacturing and applying the coating, which will act as a protective layer for the metallic structure, extending its useful life by up to 10x. Greater benefits with CMC TECHNOLOGY: Longer lifespan compared to other items on the market; Reduced maintenance costs; Efficiency in transport and material flow control; Resistance to wear from abrasion and corrosion; High warranty against wear and tear; Suitability to transported materials. Projects developed according to the client's needs: In order to transport the materials continuously, horizontally or slanted, in a single or reversible way, the conveyor is composed by joining the modules: - Input module: Product loading chute;

- Intermediate Module;

- Discharge module: Where the drive reducer motor and discharge chute are installed.

The use of the endless screw type helical system allows the material to be received either by the load chute or by any other installed in the intermediate module. It is also possible to install additional discharge chutes. The equipment can be manufactured with reversible flow, which allows for a double direction of loading and unloading and can also work with a double-thread system, one left and one right, allowing the receipt of the product coming from both ends and unloading through the center. Quality standard: The conveyors manufactured by CMC Tecnologia are a reflection of an investment in processes, development, technology and the highest quality raw materials, in addition to investing in the professional training of our employees, aiming at delivering products that lead the market in quality, efficiency and cost benefit. Grain Conveyor Screw: Agriculture is the most solid pillar of the Brazilian economy and that is why the technology used in the sector must always be of the highest quality. Among the numerous machines needed between planting and marketing crops, the grain conveyor screw serves to automate the transport of large quantities of goods, speeding up the loading and unloading system for mills, silos, trucks, bagging machines, extruders, among others . It is also useful for the continuous transport of cereals, grains, feed. How to request a quote for the screw conveyor? To request a quote there are 3 possible ways, through our WhatsApp at +55 (48) 99987-1378 or through the chat in the lower left corner of the screen (if you have closed, reload the page and you can view it again), or you can fill in the field below with your name and email to get in touch, we guarantee a quick return with your budget.Helical Conveyors coated in Hardtec ceramic.

Did you find what you were looking for?

Fill out the form and we will get back to you as soon as possible.

Enter your best email and download our catalog now.

Other products

High-performance equipment and components

Get in touch

Boost your performance with CMC

Contact Us

Adress

AV. Roberto Galli, 1220, Distrito Industrial

Cocal do sul - SC - CEP 88845-000

View on map© 2024 CMC Soluções Industriais — Todos os direitos reservados.

Desenvolvido por Cayman Sistemas | Layout por Empória Branding | Termos de Uso | Política de Privacidade